Sandblasting is a fundamental process for preparing metal surfaces, used to clean, smooth, or modify the surface properties of metal before further treatments such as painting or galvanizing. Over the years, sandblasting has evolved thanks to the introduction of advanced abrasive materials and precision techniques that allow for better results while reducing environmental impact.

Sandblasting is a fundamental process for preparing metal surfaces, used to clean, smooth, or modify the surface properties of metal before further treatments such as painting or galvanizing. Over the years, sandblasting has evolved thanks to the introduction of advanced abrasive materials and precision techniques that allow for better results while reducing environmental impact.

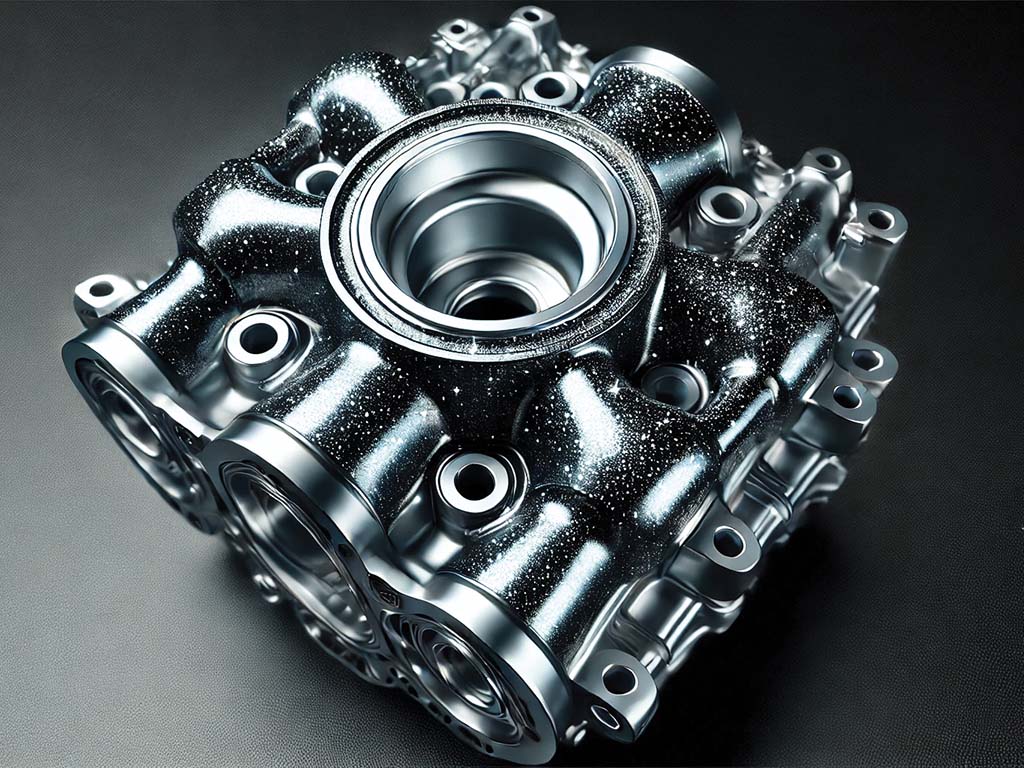

Modern sandblasting processes utilize eco-friendly abrasives, such as glass beads or recyclable materials, to replace traditional silica sands, which can be hazardous to health if inhaled. Additionally, closed-loop sandblasting systems have been developed, allowing for the reuse of abrasive materials and reducing dust emissions into the environment. This is particularly important for the automotive and aerospace industries, where surface precision and cleanliness are paramount.

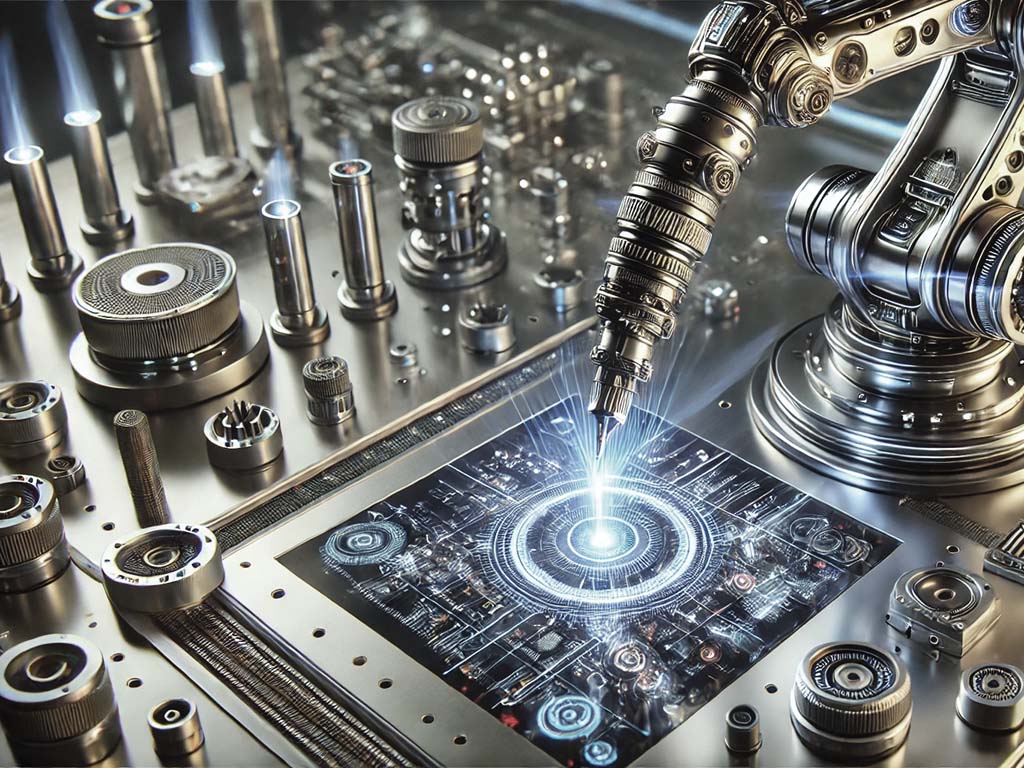

Another innovation is the use of high-pressure water blasting (hydro-blasting), which combines the abrasive power of water with abrasive particles, allowing for deeper cleaning while minimizing environmental impact. This technique is ideal for removing paint or rust without damaging the underlying material, making it perfect for the maintenance of large metal structures or industrial equipment.

These advancements are transforming metal cleaning, making it more efficient, precise, and environmentally friendly. As technology continues to evolve, we can expect further improvements in sandblasting techniques, contributing to more sustainable and effective industrial processes.