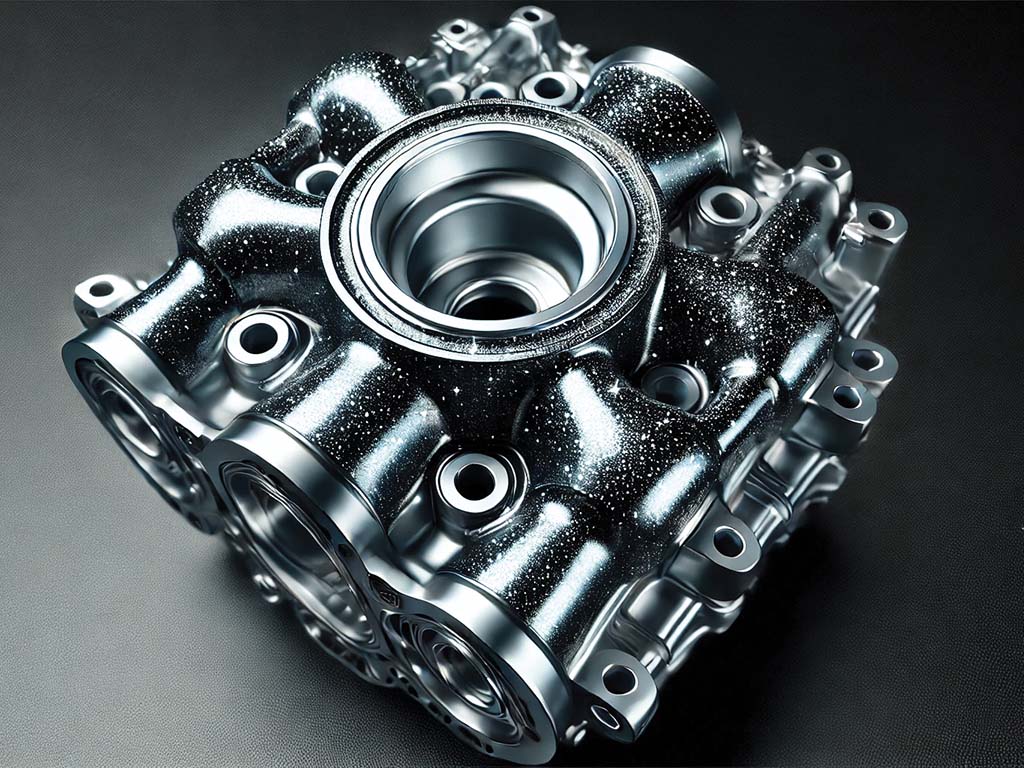

Galvanization is a surface treatment technique that has undergone numerous technological evolutions, remaining one of the most efficient methods for protecting metals from corrosion. The process involves coating a metal surface with a layer of zinc, a material that offers superior protection against oxidation and rust. Today, galvanization is industrially applied to components of all sizes, especially in sectors such as automotive, construction, and infrastructure.

Galvanization is a surface treatment technique that has undergone numerous technological evolutions, remaining one of the most efficient methods for protecting metals from corrosion. The process involves coating a metal surface with a layer of zinc, a material that offers superior protection against oxidation and rust. Today, galvanization is industrially applied to components of all sizes, especially in sectors such as automotive, construction, and infrastructure.

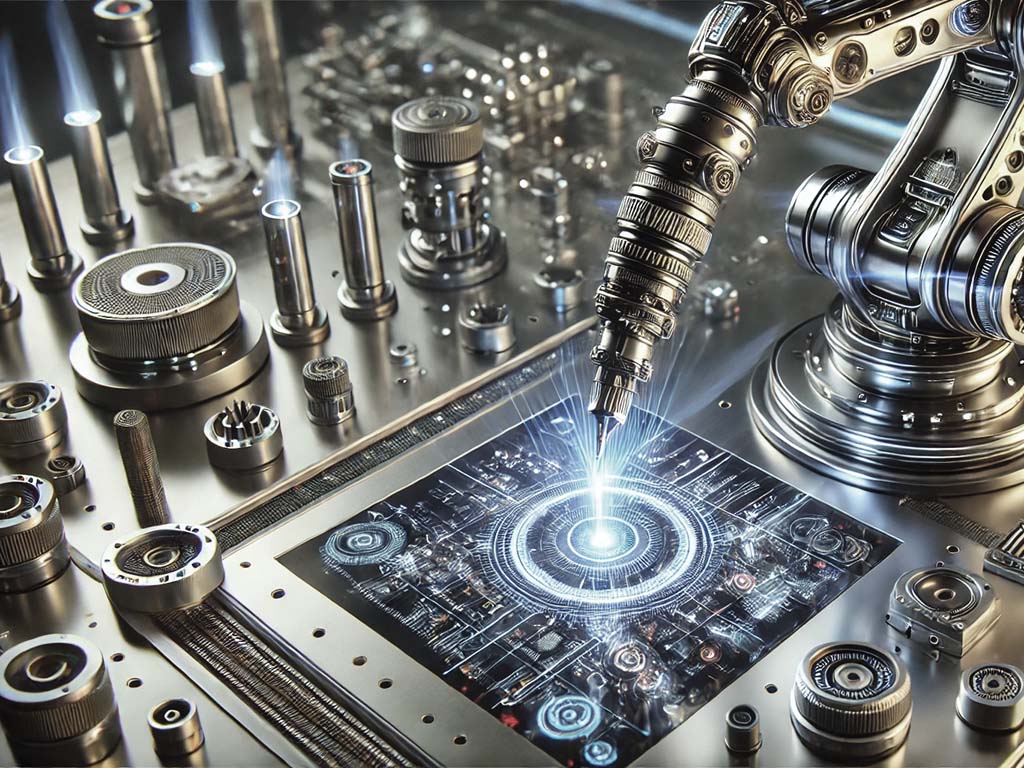

The most advanced technologies in the field of galvanization include the use of electrolytic galvanization, a process that allows for a uniform and controlled application of zinc through electrolysis. This technique not only improves the adhesion of the protective layer but also enables the management of minimal thicknesses, essential for ensuring lightness in components without sacrificing protection. Another advantage is the possibility of combining galvanization with passivation treatments, which reduce the need for long-term maintenance.

In the future, we expect to see even greener solutions, with increased use of recycled zinc and low-energy consumption processes. Researchers are also working on variants of galvanization that incorporate nanomaterials, further enhancing resistance to atmospheric agents and prolonging the lifespan of exposed components.