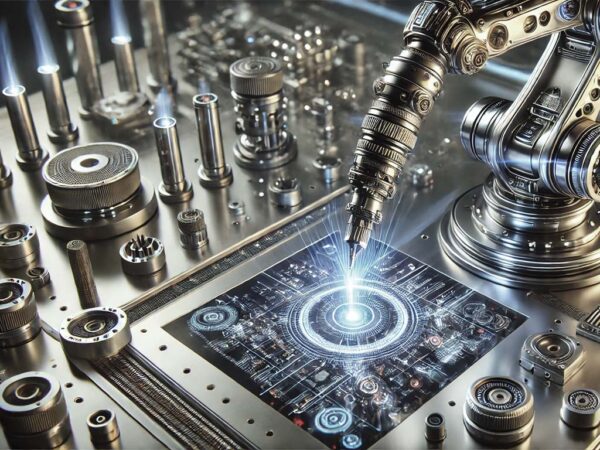

In the era of Industry 4.0, metal surface treatments are undergoing a major transformation thanks to the integration of advanced technologies such as automation, robotics, and artificial intelligence (AI). These innovations significantly enhance the efficiency of production processes, reducing processing times and improving precision.

In the era of Industry 4.0, metal surface treatments are undergoing a major transformation thanks to the integration of advanced technologies such as automation, robotics, and artificial intelligence (AI). These innovations significantly enhance the efficiency of production processes, reducing processing times and improving precision.

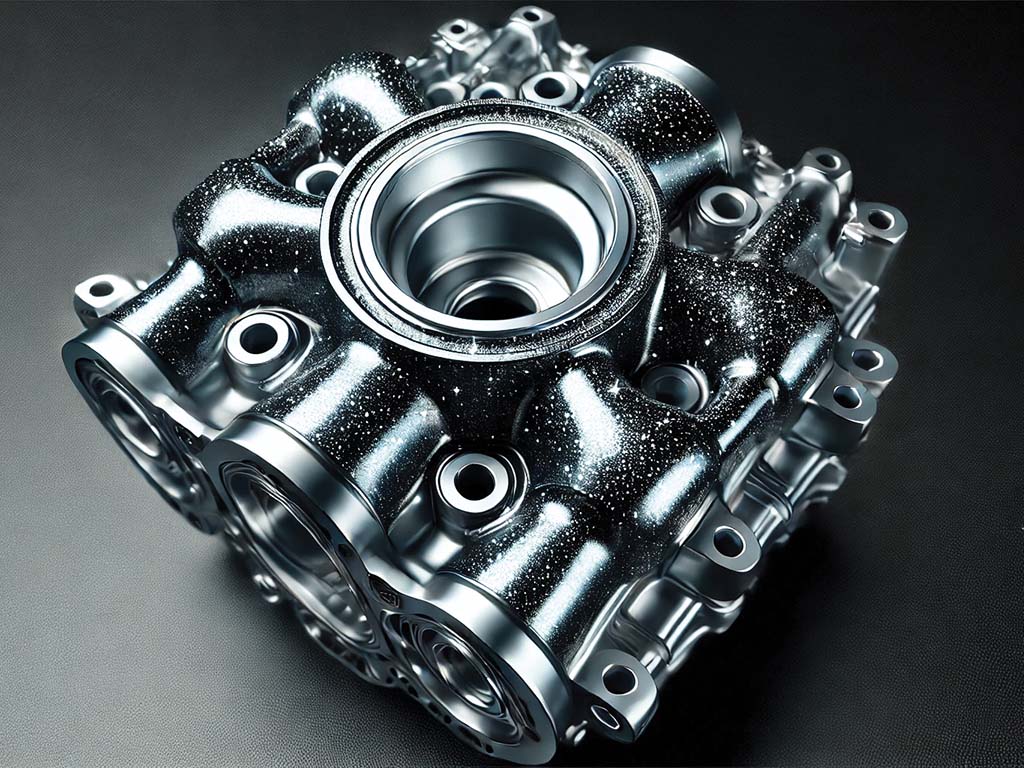

Surface Treatments 4.0 rely on computer-controlled systems that allow real-time monitoring of every stage in the process. This not only reduces the risk of human error but also enables optimization of processing parameters, ensuring extremely high-quality results. For instance, the use of collaborative robots (cobots) allows for zinc plating or sandblasting operations to be carried out with a level of precision that surpasses manual methods, particularly in hazardous or hard-to-reach environments.

Moreover, the integration of AI in quality control processes is revolutionizing the way inspections are conducted. With the use of advanced sensors and machine learning algorithms, it is now possible to detect defects that are invisible to the human eye, significantly improving the final quality levels of treated products.

These technological advancements are also making surface treatments more sustainable, by reducing waste and energy consumption. The future of metal treatment is increasingly interconnected, with smart systems capable of quickly adapting to market demands and ensuring highly customized production.